Countersunk Head Chipboard Screw

Countersunk Head Chipboard Screws are a type of fastener designed specifically for use in chipboard and other types of wood. They feature a flat, tapered head that sits flush with the surface of the material when fully installed, providing a smooth and seamless finish. These screws have coarse threads that provide excellent grip and pull-out resistance in wood, ensuring a secure and reliable connection. With their sharp points, they can easily penetrate the material without the need for pre-drilling, saving time and effort during installation. Countersunk Head Chipboard Screws are commonly used in various woodworking applications, such as furniture assembly, cabinet construction, and general carpentry projects.

- Commodity name: Countersunk Head Chipboard Screw

- Commodity ID: cp1101

- Description

-

Product introduction

Chipboard screw is a kind of product with heat treatment process, which is suitable for the installation of electric tools. It is mainly used for the connection and fastening between wood plates and thin steel plates.

Product parameter

Certification: ISO9001, SGS, CTI, ROHS

Material: C1022a

Head Type: flat/countersunk

Finish: yellow zinc, black phosphate, gray, white zinc, HDG, respect, nickel, and so on

Diameter: 3.5mm-6mm

Length: 13mm-100mm

Thread: full thread, partial thread

Point: sharp

Drive: Philips, Pozi, socket, hex, square, slotted, combined

Packing: Bulk, small box, plastic box, polybag, etc, according to customers’ demandProduct application

In the whole fastener industry, this product is as important as drywall screw and has a huge sales volume. It is widely used in furniture manufacturing and other industries. At present, domestic consumers purchase this variety in the building materials supermarket, mainly used to install guide rail, hinge, cooperate with fish expansion installation and replace wood screw installation to make furniture, cabinet, etc.

The Countersunk Head Chipboard Screw is an indispensable product in the fastener industry, renowned for its heat-treated construction. This screw is specifically designed for electric tool installation and is widely used for connecting and fastening wood plates and thin steel plates. Its significance is comparable to that of the popular drywall screw, boasting a high sales volume globally.

In the realm of furniture manufacturing and related industries, the Countersunk Head Chipboard Screw holds immense importance. It finds widespread application in the installation of guide rails, hinges, and serves as a reliable alternative to wood screws during the assembly of furniture, cabinets, and other wooden structures. This versatile screw can also be utilized in conjunction with fish expansion installations, providing enhanced stability and strength.

One of the notable attributes of the Countersunk Head Chipboard Screw lies in its appearance. Featuring a flat, tapered head, it seamlessly blends into the material it fastens, ensuring a smooth and professional finish. This flush installation not only enhances the visual appeal but also minimizes the risk of snagging or catching on surrounding objects.

The benefits of using Countersunk Head Chipboard Screws extend beyond aesthetics. With its heat-treated construction, this screw exhibits remarkable durability and resilience, capable of withstanding substantial pressure and torque. Its coarse threads ensure a dependable grip and prevent loosening over time, guaranteeing a secure and long-lasting connection.

Moreover, the Countersunk Head Chipboard Screw offers exceptional convenience during installation. Thanks to its sharp point, pre-drilling is unnecessary, saving valuable time and effort. This feature, combined with its compatibility with electric tools, streamlines the installation process and facilitates efficient work.

In summary, the Countersunk Head Chipboard Screw is a vital component in the fastener industry, featuring heat-treated construction for optimal strength and durability. Whether used in furniture manufacturing, cabinet construction, or general woodworking projects, this screw provides a secure and seamless connection between wood plates and thin steel plates. Its flush appearance, ease of installation, and reliable performance make it a preferred choice for professionals and consumers alike.

Factory Tour

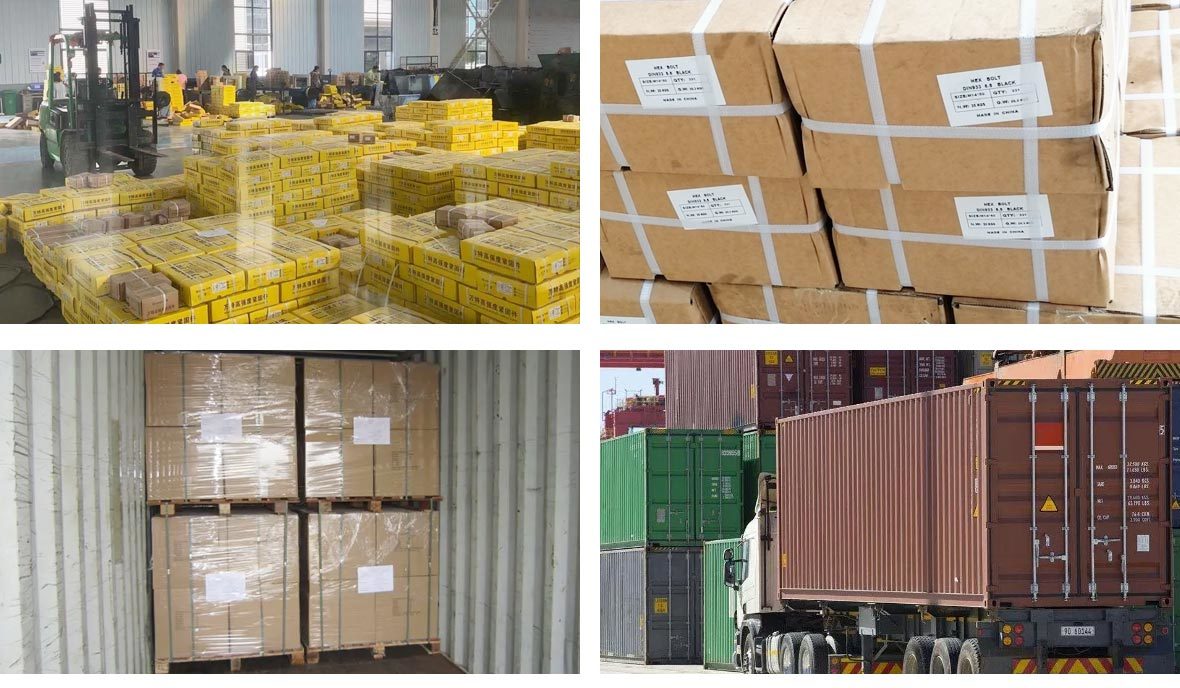

Packing & Delivery

FAQ

1. who are we?

We are based in Hebei, China, start from 2020,sell to Domestic Market(00.00%). There are total about 301-500 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Splice Bolts/Hex Bolts,Hex Nuts,Cross Slotted Screws,Seismic Support

4. why should you buy from us not from other suppliers?

Yibang Machinery Technology company covers an area of about 75,000 square meters, with a registered capital of 60 million yuan and 350 employees. Committed to strict quality control and considerate customer service, our experienced staff can discuss your r

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!